Clear plans save lives, support OSHA compliance, and build a calm, safety-first culture.

Table of Contents

Emergencies can happen in any workplace at any time. Fires, chemical releases, severe weather, and medical events put workers at real risk. Without planning, injuries and fatalities rise. With a clear Emergency Action Plan (EAP), organizations protect people, support OSHA compliance, and reduce chaos.

OSHA and Compliance Context

OSHA requires many U.S. employers to maintain a written emergency action plan under 29 CFR 1910.38. Exit route design and maintenance also fall under 1910.36 and 1910.37. Compliance reduces risk and helps prevent citations.

Why Emergency Action Plans Matter

- Protect life: Clear steps for fires, chemical releases, severe weather, medical emergencies, and threats.

- Reduce panic: Workers know where to go and what to do.

- Speed evacuation: Marked routes and roles move people fast.

- Support compliance: Aligns with OSHA standards and reduces liability.

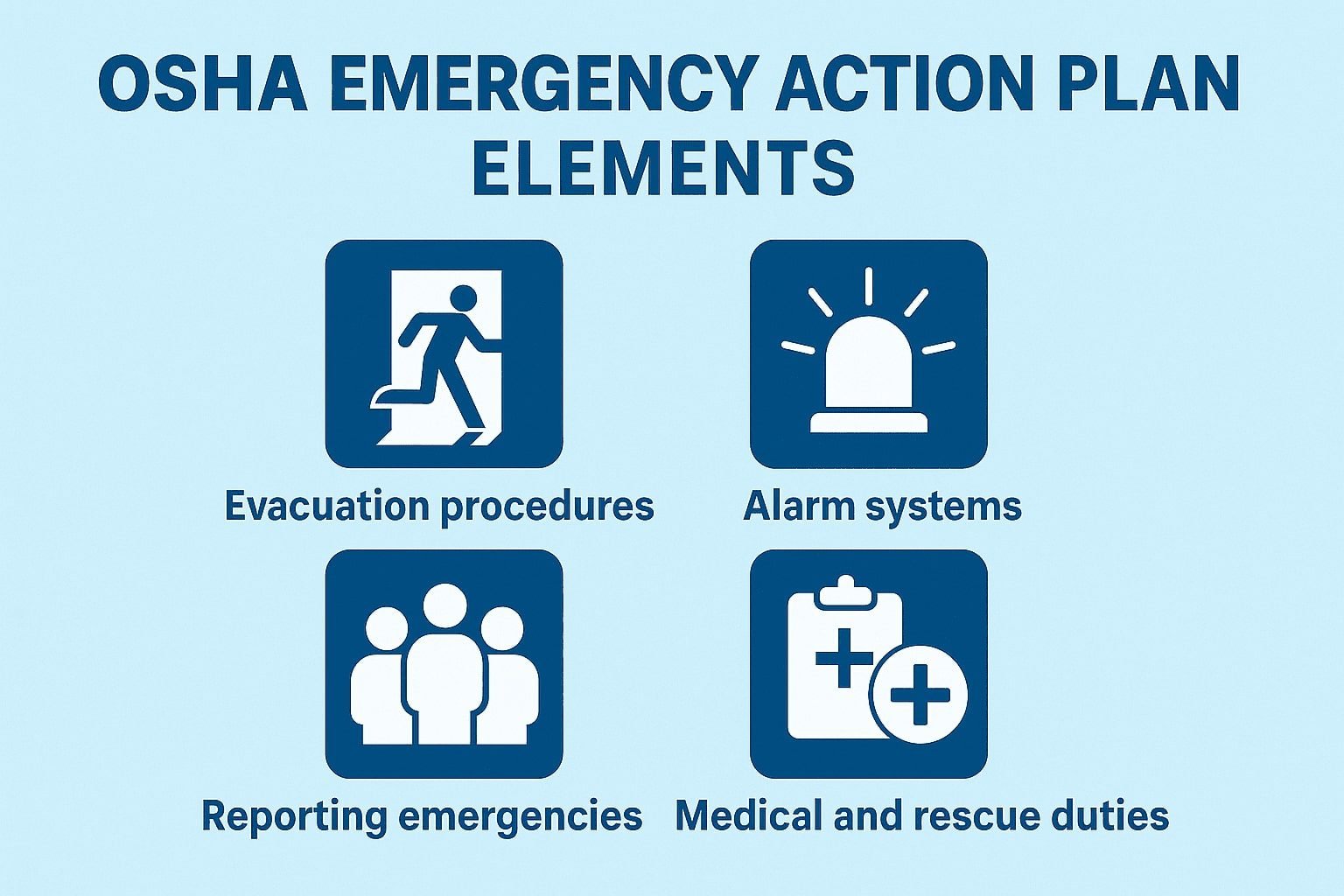

Core Elements of an Emergency Action Plan

🚪 Exit Routes

Keep routes marked, illuminated, and free of obstructions. Doors must open in the direction of travel in most high-occupancy areas.

🔔 Alarms

Use audible and visual alarms so all workers, including those with hearing or vision impairments, receive alerts.

📣 Reporting

Define how to report fires, spills, medical events, and threats. Include backup methods.

👥 Roles & Training

Assign coordinators, floor wardens, and first aid leads. Run drills so every shift knows the plan.

Workplace Scenarios Where EAPs Save Lives

🔥 Fire in a Warehouse

Orderly evacuation through marked exits prevents smoke inhalation and burns.

🧪 Chemical Release

Shelter-in-place or evacuation steps limit exposure and guide decontamination.

🌪️ Tornado Warning

Workers move to interior safe zones and maintain accountability until all clear.

The Human Side: Employee Confidence & Safety Culture

🧠 Calm Action

Training and drills help workers act with confidence. People react faster when they have practiced the exact steps.

🤝 Safety-First Mindset

Regular communication, visible signage, and leadership support build a culture where safety is part of every task.

Common Mistakes Companies Make

Treating the EAP as paperwork only.

Failing to update the plan after layout or process changes.

Not training new employees or providing refreshers.

Ignoring site-specific hazards and regional weather risks.

Key Statistics That Prove the Need

Organizations with effective emergency response plans experience a fraction of the losses vs. those without robust plans. U.S. Chamber

EAP Checklist ✅

Quick Tips 💡

FAQs

What emergencies should an EAP cover?

Who writes the EAP?

How often should drills be conducted?

Is an EAP required in every workplace?

Key Takeaway: A well-built Emergency Action Plan saves lives, reduces panic, and supports OSHA compliance. Keep routes clear, assign roles, train often, and update the plan as your workplace changes.

Sources: OSHA 1910.38 • OSHA 1910.36 • OSHA 1910.37 • OSHA Common Stats • CDC • BLS • U.S. Chamber of Commerce