Stay safe by understanding top electrical hazards at work and how Lockout/Tagout prevents injuries.

Introduction: Why Electrical Hazards Matter

Working with electricity is dangerous. Each year, hundreds of U.S. workers are killed or seriously injured by electrical accidents. Many of these tragedies happen because machines were energized when someone thought they were safe. The good news is that most electrical injuries can be prevented when workers follow safe practices and apply Lockout/Tagout (LOTO).

OSHA and U.S. Compliance Context

The Occupational Safety and Health Administration (OSHA) sets strict rules for controlling hazardous energy. Two standards are most important for workers:

- OSHA 29 CFR 1910.147: The Lockout/Tagout (Control of Hazardous Energy) standard.

- OSHA Subpart S (Electrical Safety): Covers safe use of electrical equipment and systems.

Employers must train workers, provide proper lockout/tagout devices, and enforce safe practices. Following these standards not only prevents accidents but also supports compliance and reduces workplace risks.

Common Electrical Hazards in the Workplace

- Live wires and energized equipment – touching live circuits can cause shock or death.

- Arc flashes and blasts – sudden energy releases that burn skin and damage eyes.

- Faulty tools or damaged cords – cracked insulation and exposed wires increase risks.

- Overloaded circuits and poor grounding – lead to overheating and fires.

- Stored energy in machines – equipment may restart without warning if not isolated.

How Lockout/Tagout Prevents Electrical Injuries

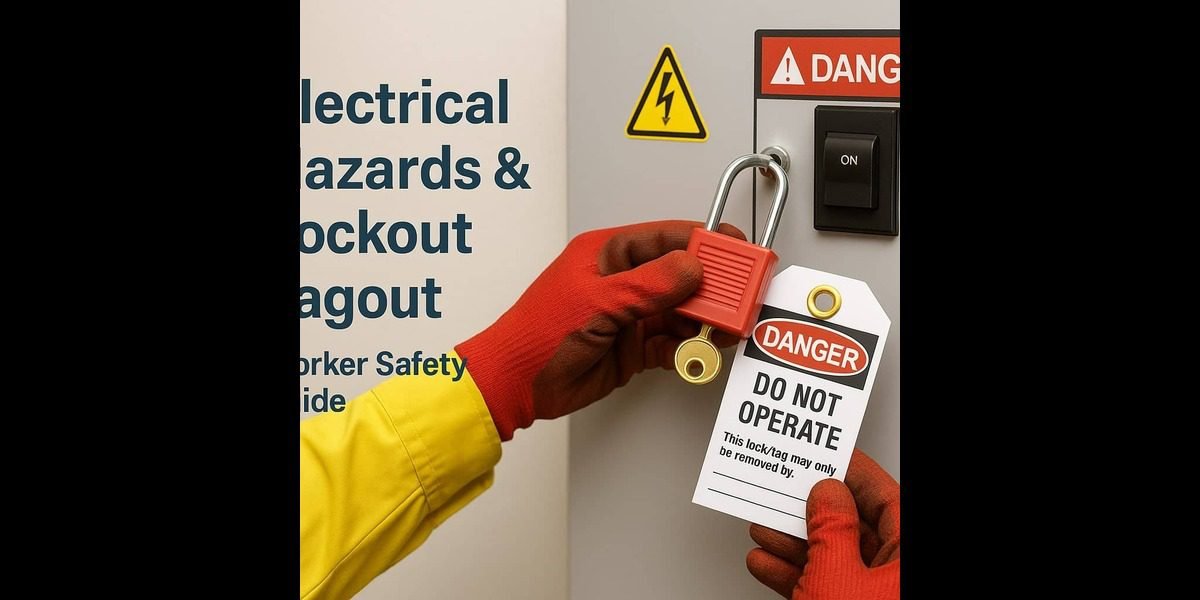

Lockout/Tagout is designed to protect workers from unexpected energization. It works by:

- Isolating energy sources – turning off and disconnecting all power.

- Applying locks and tags – physical devices that keep switches and valves in the “off” position.

- Giving control to workers – only the person who placed the lock/tag can remove it.

Step-by-Step: Applying Lockout/Tagout

- Notify affected employees.

- Shut down equipment properly.

- Isolate all energy sources.

- Apply lockout and tagout devices.

- Release any stored energy.

- Verify equipment is de-energized.

- Remove locks and tags after work is complete.

- Inform workers nearby

- Power off equipment

- Disconnect energy sources

- Apply lock and tag device

- Drain stored energy

- Test for zero energy

- Remove lock/tag after task

Real Impact: How LOTO Saves Lives

Failure to use lockout/tagout is a leading cause of workplace electrocutions. According to OSHA, proper LOTO procedures prevent an estimated 120 fatalities and 50,000 injuries every year.

For example:

- A worker repairing a conveyor belt was killed when another employee unknowingly restarted the machine.

- An electrician suffered severe burns when stored energy inside a circuit was not discharged before work began.

Both tragedies could have been avoided with LOTO. Simple steps truly save lives.

Worker’s Role in Ongoing Safety

- Training: OSHA requires that all “authorized employees” receive lockout/tagout training.

- Periodic inspections: Employers must review LOTO procedures at least once a year.

- Reporting hazards: Workers should report damaged cords, missing guards, or unsafe practices immediately.

FAQs

Who needs LOTO training?

Any worker who services or maintains machines and could be exposed to hazardous energy must receive training.

What happens if a lock is removed without permission?

Removing another person’s lock is a serious violation and can lead to fatal accidents. Only the worker who applied the lock may remove it.

Are tags alone enough for compliance?

No. Tags warn others, but they do not physically stop equipment from starting. OSHA requires locks whenever possible.

Conclusion

Electrical hazards are among the deadliest risks in the workplace. But with the right knowledge and strict use of Lockout/Tagout, workers can prevent shocks, burns, and fatalities. The safest approach is simple: follow LOTO every time. By doing so, workers protect themselves and their coworkers from life-changing accidents.